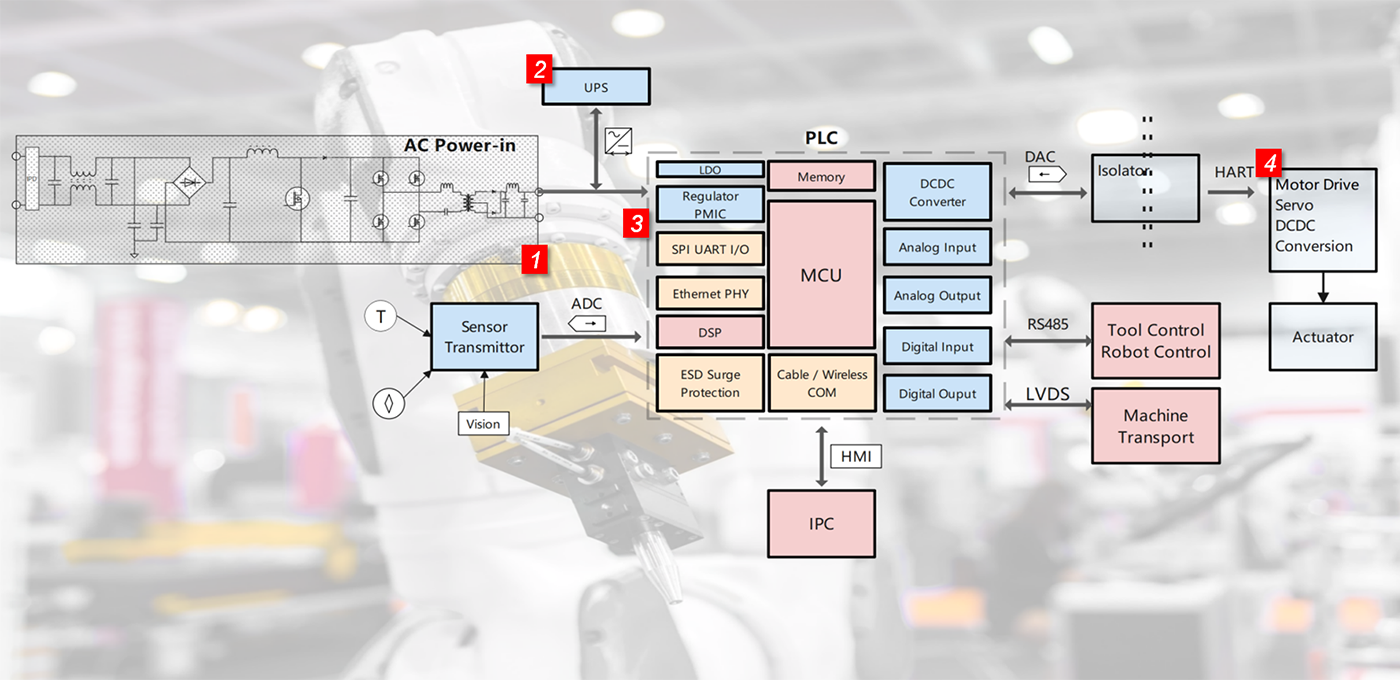

Intelligent factories utilize PLC(Programmable Logic Controller) for monitoring working environment as well as controlling manufacturing automation. At the heart of it there are microcontrollers running by codes from operation systems, and it provides HMI (Human Machine Interface) for supervising the process. There are different communication from cable wires to wireless connection in order to monitor harsh environmental parameters for example of temperature, humidity and vibration that signal generated by sensors, after then the PLC also to be programmed for activating real-time actuators such as switches, brakes or motors.

Because of its system complexity and flexibility, there are several hosts, nodes and downstream function units such as tools, robots or transport lines which all need robust, safe and interference compatible voltage rails or power supplies - from AC power-in to miscellaneous voltage regulators both isolated or non-isolated. For that purpose, the components applied into industrial has to be with more robustness, withstanding over currents especially when the circuit been shorted, bearing with wider operation temperatures but also being power efficient at the same time.