This article aims to provide a detailed explanation of the working principles and applications of Ferrite beads.

1. Principles of Ferrite Beads

A ferrite bead, also known as a magnetic bead filter, is an EMI noise suppression component designed to mitigate high-frequency noise. While its physical appearance resembles an inductor and shares similar operating principles (thus some manufacturers to classify it as an inductor), its core mechanism differs. Inductors store energy and suppress noise through "peak shaving and valley filling" (smoothing current fluctuations) based on Lenz’s Law. However, inductors incur copper and core losses during filtering.

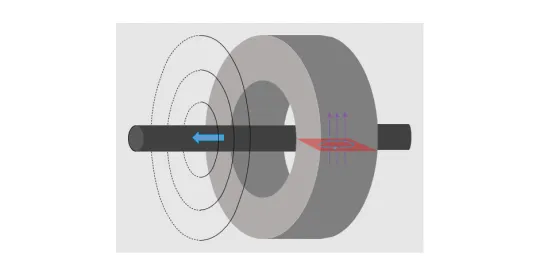

Ferrite Beads primarily rely on core losses (hysteresis loss and eddy current loss) for noise suppression. When current passes through the bead, it generates a magnetic field. Rapid current changes induce an internal electric field within the ferrite core (see red cross-section in Figure 1), creating eddy currents. Due to the core’s high resistivity, these eddy currents dissipate as heat, achieving "peak shaving" noise attenuation. Ferrite beads also exhibit minor inductance, contributing to secondary "valley filling" effects. Their impedance is measured in ohms (Ω), making them ideal for suppressing high-frequency noise in power or signal lines (Figure 1).

[Figure 1: Core Filtering Mechanism of Ferrite Beads]

The core material of ferrite beads is typically made from nickel-zinc ferrite, though amorphous tape or nanocrystalline tape can also be used. These beads come in various shapes, including single-hole (RH), dual-hole (RID), and six-hole (R6H) designs, but their primary function is to suppress noise. The installation methods for ferrite beads are mainly divided into two types: through-hole (TH) and surface-mount (SMT), with through-hole type further categorized into vertical and horizontal orientations.

2. Key Applications of Ferrite Beads

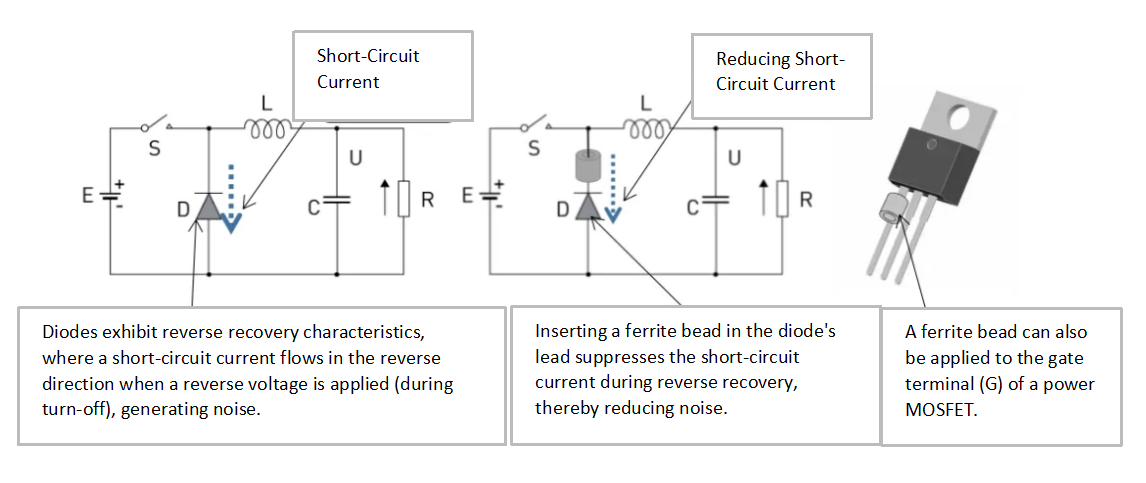

The primary purpose of magnetic beads is to suppress noise generated by the reverse recovery characteristics of diodes or MOSFETs.

As shown in Figure 2, in the switching circuit of a DC-DC converter, the current flowing through the diode does not typically move from the anode to the cathode. When a reverse voltage is applied to the diode while forward current is flowing, the diode current is expected to cease immediately. However, in practice, a large reverse current flows through the diode for a short period. This phenomenon is known as the reverse recovery characteristic of the diode, and the duration of this current flow is termed the reverse recovery time.

Since this loop serves as the main current path, the resistance in this loop is designed to be as low as possible. This design constraint results in a lack of current limiting during the reverse recovery process, leading to extremely high short-circuit currents. These currents are a primary cause of significant power losses or substantial noise generation in diodes.

[Figure 2: Switching Circuit in a DC-DC Converter]

In switching power supplies, the reverse recovery characteristics of diodes, combined with the operation of switching transistors (power MOSFETs), are a major source of noise. By integrating ferrite beads into the diode leads, an inductive coil can be formed, effectively suppressing the short-circuit current caused by reverse recovery and reducing noise. High-speed diodes exhibit reverse recovery times in the nanosecond range, and the resulting short-circuit current can reach tens of amperes. While adding resistors could theoretically suppress this noise, such an approach would introduce significant power losses and voltage drops. Therefore, ferrite beads are prioritized for their ability to mitigate noise without introducing wasteful power dissipation or additional voltage drops.

Ferrite beads are not only used in power lines but also serve as high-frequency filters in various signal transmission circuits. To address high-frequency EMI challenges, Codaca offers a comprehensive range of ferrite beads series, including the RH Series, RHD Series, RID Series, RHV Series, and SMB Series, catering to both through-hole and surface-mount installation requirements.

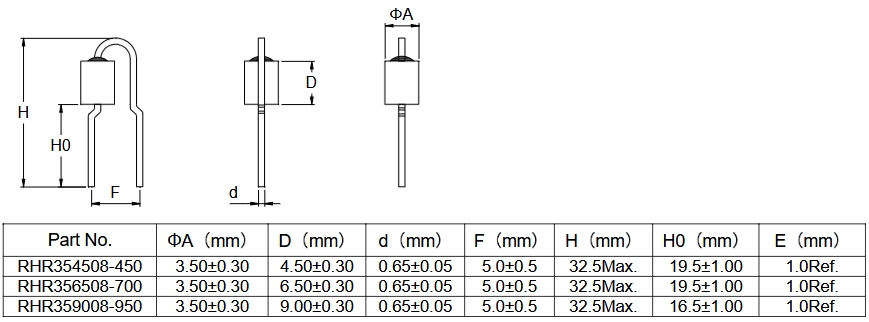

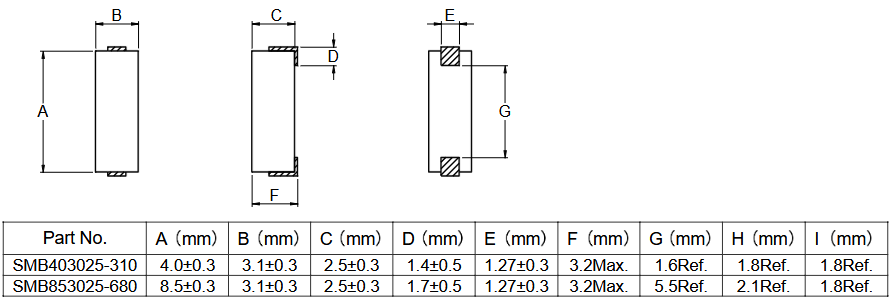

Please refer to the following representative ferrite beads from Codaca.

[Figure 3: Through-Hole Beads, RHR Series]

[Figure 4: High-Current SMD Beads, SMB Series]

Learn more at: https://www.codaca.com/Productsctr_Bead.html

3.Conclusion

As electronics trend toward high frequencies, it results in no only the trend towards higher frequencies in electronic products has led to miniaturization and energy efficiency, but it also introduced electromagnetic compatibility (EMC) challenges at high frequencies. Traditional inductors struggle with electromagnetic interference (EMI) handling in high-frequency range. To address EMI issues in high-frequency range, ferrite beads have emerged as a solution.

To help electronic devices solve high-frequency EMI problems, CODACA has developed a range of standardized power inductors, common mode choke, and various structural types of ferrite beads.