In power supply design, GaN-based solutions enable higher switching frequencies, superior thermal performance, and significantly reduced device size and weight—more than 50% smaller compared to silicon-based solutions. This saves substantial installation space, minimizes overall system dimensions, and greatly enhances power density. As a result, GaN devices demonstrate core advantages such as high power density, low energy consumption, and high reliability in applications like 5G communications, electric vehicles, data centers, and server power supplies. With their expanding application, higher demands are placed on inductor performance in circuits.

1. Inductor Requirements for GaN Power Systems

● High Frequency, Low Loss

GaN devices support MHz-level high-frequency switching, which effectively reduces passive component size. However, high frequencies result in skin effects and core losses in inductors. Thus, inductors must utilize low-loss materials to prevent core heating at high frequencies.

● High Saturation Current

The high power density of GaN systems may subject inductors to higher transient currents, risking core saturation. Materials like Fe-Si-Al or Fe-Ni alloys with high saturation flux density (Bs) are preferred to prevent sudden inductance drops under high current while ensuring stable electrical performance under dynamic loads.

● Low DC Resistance (DCR)

Minimizing copper loss is critical for improving GaN system efficiency. Techniques like thicker wire gauges or flat-wire windings reduce DCR by increasing conductor cross-sectional areas.

● Miniaturization and High Power Density

GaN systems pursue extreme compactness. Inductors with high-Bs materials and distributed gap designs minimize core size, reducing PCB footprint.

● Temperature Stability

Inductor parameters (e.g., inductance, losses) varying with temperature can destabilize power systems. Materials with stable thermal properties ensure consistent performance across a wide temperature range (-55℃ to +150℃).

2. CSBA High Current Power Inductor Series: Tailored for GaN Power Solutions

To meet the demands of high-frequency GaN applications——particularly for low loss, high power density, and wide-temperature performance——Codaca released the CSBA high current power inductor series. Designed with innovative alloy powder core, this series offers excellent soft saturation characteristics, and high-frequency efficiency. Extensive testing approved that the CSBA series achieves minimal loss at 300~600 kHz, making it ideal for GaN-based designs.

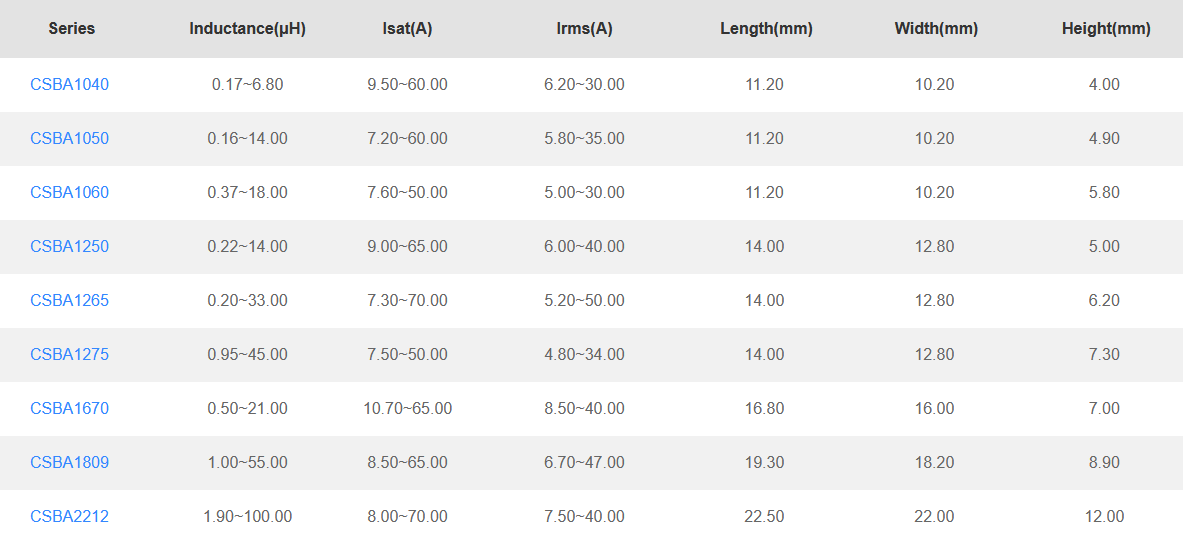

The high current power inductor CSBA series is available in nine types of sizes, which includes CSBA1040, CSBA1050, CSBA1060, CSBA1250, CSBA1265, CSBA1275, CSBA1670, CSBA1809, CSBA2212. The inductance of these fixed inductor ranges from 0.17μH to 100μH, DCR low to 0.32mΩ, saturation current up to 70A, and working temperature -55℃~+150℃.

【SAMPLE APPLY】

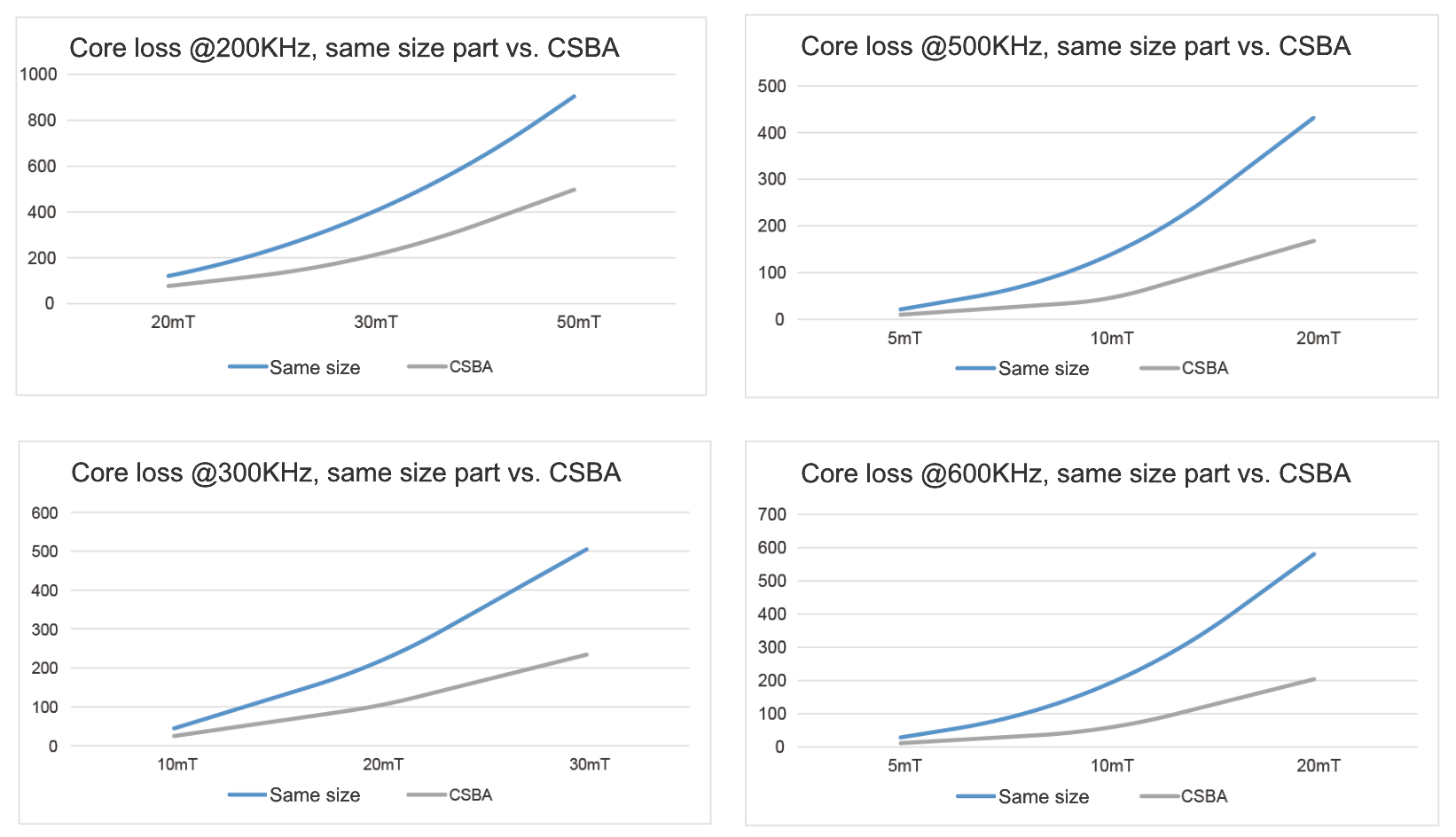

1) Low Core Loss for GaN High-Frequency Operation

GaN’s high-frequency operation demands inductors with minimal core losses. The high current power inductor CSBA series employs low-loss materials and flat-wire winding designs to reduce core losses and DCR, enhancing power conversion efficiency. Comparative data on core losses between standard alloy powder inductors and the CSBA series across frequencies are shown below.

2) Magnetic Shielding for EMI Suppression

The compact high current power inductor CSBA series integrates magnetic shielding to effectively suppress electromagnetic interference (EMI) which is critical in high-frequency GaN application. By minimizing interference with sensitive components, it enhances signal integrity and system reliability, ideal for high-density applications like data center server power supplies.

3) Ultra-Compact Design for High Power Density

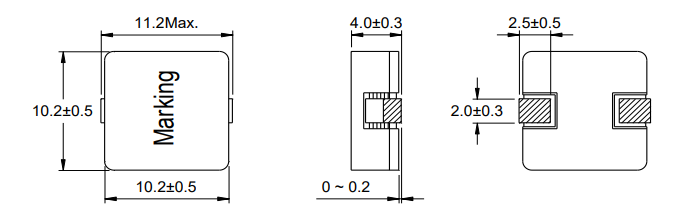

With a slim profile and compact structure (minimum size: 11.20 X 10.20 X 4.00 mm), the high current power inductor CSBA series saves PCB space and supports high-density mounting, meeting the stringent space utilization requirements of modern electronic devices.

CSBA1040 Size

4) Wide-Temperature Stability

Operating from -55℃ to +150℃, the compact high current power inductor CSBA series maintains low losses and high efficiency even in high-temperature environments, effectively preventing thermal aging issues.

5) Low Loss, High Efficiency

Advanced alloy powder cores and optimized coil structures minimize core and resistive losses, improving overall GaN system efficiency. For instance, in server power supplies, low-loss inductors reduce energy waste, aligning with green energy trends.

6) Broad Application Compatibility

The high current power inductor CSBA series is widely applicable to GaN-based DC-DC converters, switching regulators, and core modules in AI server power supplies or new energy equipment. Its high-current handling and high-frequency adaptability support high-power-density designs while ensuring long-term reliability.

3. Environment Standard

The compact high current power inductor CSBA series meet RoHS, REACH, and halogen-free requirements.

4. Product Status

As with all parts in CODACA, The high current power inductor CSBA series has been in mass production and lead time is 4~6 weeks.