Apr. 2024, CODACA Electronic, the global leading high current power inductor and molding power choke manufacturer, released molding power choke VSHB1060T series with a dimension of 10.85*10.20*5.80mm only, which features low core loss and high reliability for automotive and harsh environment application.

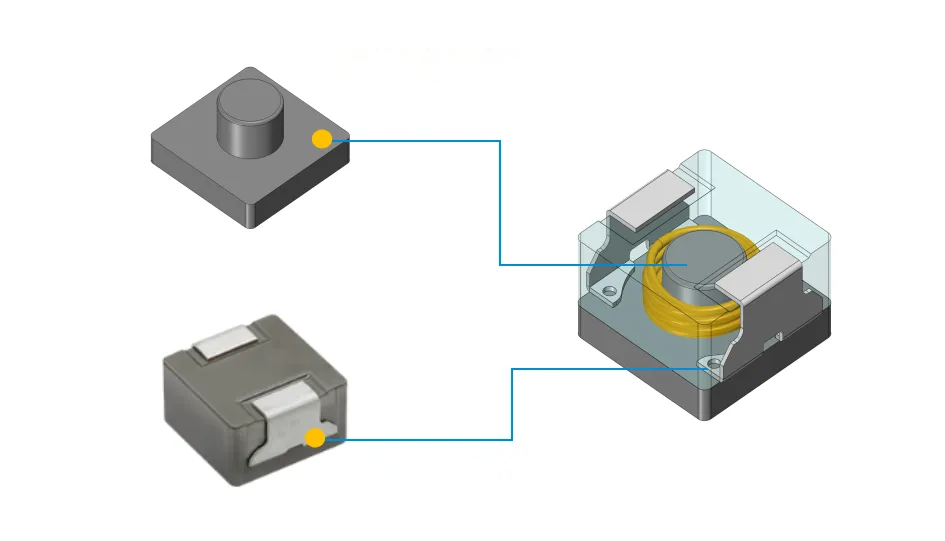

T-core Design, High Performance

The VSHB1060T series is hot molded by T-core and low loss magnetic powder, greatly improving powder density and effectively avoiding coil deformation after molding. The wider terminal design enhances SMT solidity, resulting in strong resistance to mechanical shock and vibration, up to 10G. This series core material features soft saturation, available in handling high peak current.

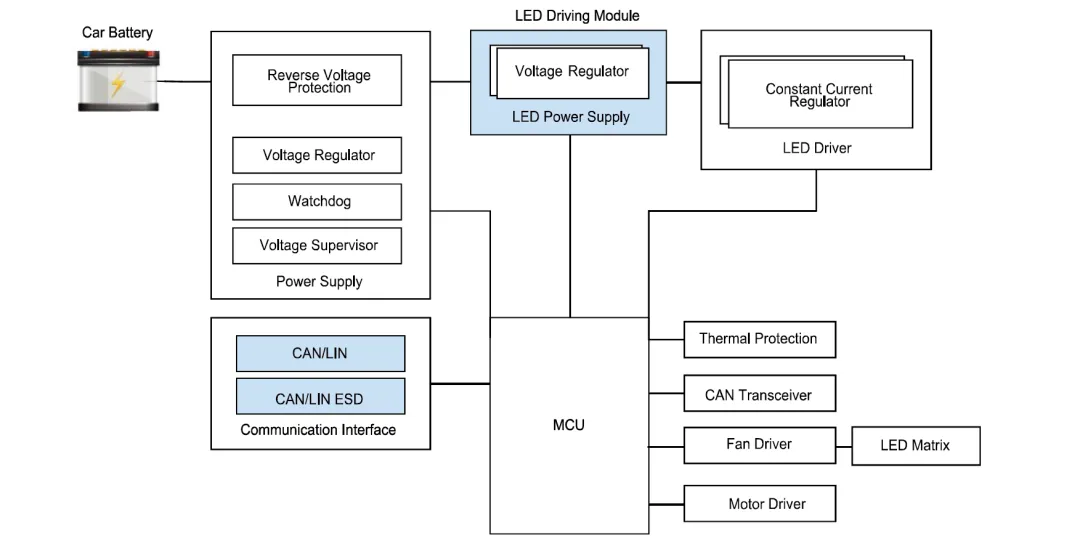

AEC-Q200 Compliant, High Reliability

The AEC-Q200 qualified VSHB1060T series are designed with enameled wire and high insulating magnetic powder, ensuring it works stably under continuous high temperature (-55℃~165℃) with no thermal aging issues, of which inductance value and saturation current are less affected by temperature rise, making them perfect for high temperature applications like car lighting, ADAS, OBC, etc. This series uses laser marking, enhancing antirust capability and traceability.

Automation Production

The VSHB1060T series realized automation production in wire winding and molding process. Strictly following the quality management system of IATF16949, the product R&D is based on APQP and PPAP in production to ensure the stability and consistency of product quality. The high automated production capacity can meet the increasing needs of automotive products customers.

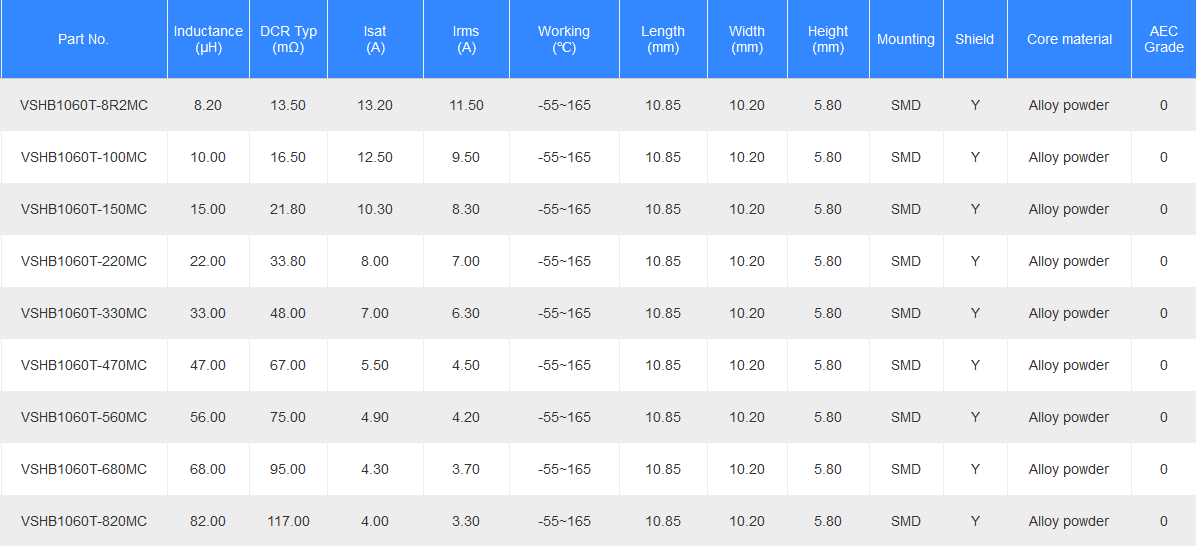

Electrical Parameters

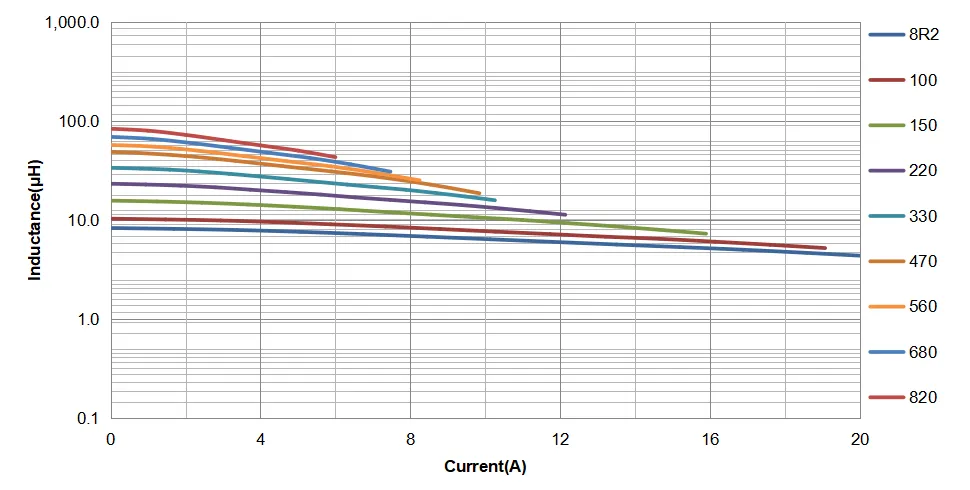

Saturation Current Curve

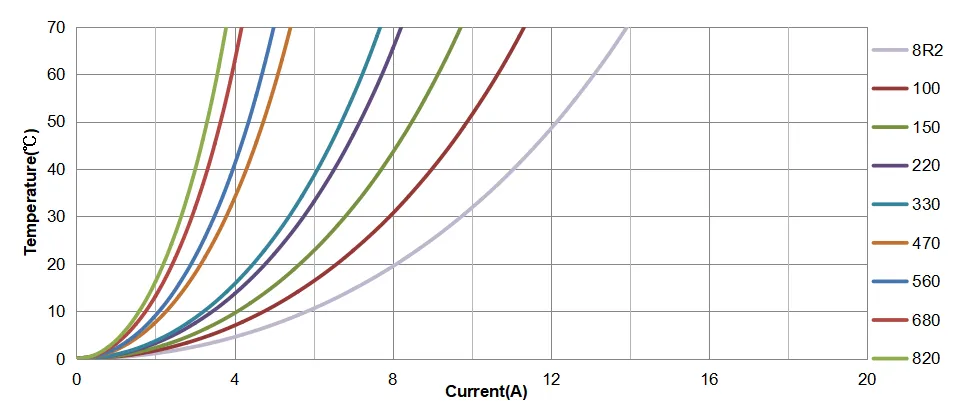

Temperature Rise Current Curve

Applications

◾ ADAS

◾ OBC

◾ Car lighting

◾ Car navigation system

◾ Engine and transmission control units

Environment Standard

The VSHB1060T series features halogen-free, RoHS and REACH compliant

Product Status

As with all parts in CODACA, VSHB1060T series has been in mass production and lead time is 4~6 weeks.

Datasheet Download: VSHB1060T.pdf

VSHB1060T.pdf